In the case that your clients / patients are not satisfied with their current knee, here are some things to consider:

Dissatisfaction can take two shapes:

1) The user does not complain, but has diminished their range of activities, or has forgotten even their own natural interests. This may be that they have learnt that they cannot walk fast, or even only with a single walking speed. They may have lost interest in going to places of interest because the grounds are uneven and perceived as scary to walk on. Or likewise, they may no longer go out for a walk with their partner out of fear of not being able to keep up.

2) User complains. The user may complain about the lack of safety, frequent falls or near falls, or may express well-out-of-budget wishes. Not knowing what joint your client currently uses, but knowing that many knee joints offer solutions or reversely lack solutions for particular use patterns, I suggest to evaluate the dissatisfaction as per the checklist of following functional issues:

- Stability / Security

- Stumble recovery

- Slope / Stairs Descent

- Heat

- Fast Walking speed

- Wet use

- Battery maintenance

- Wading through grass / water

- Flexible choice of feet

- Maximum kneeling angle

- Heaviness of the limb because they have such a short stump.

- Socket fit issues due to weight of prosthesis

In this case check out the VGK-S for amputees with short transfemoral stump.

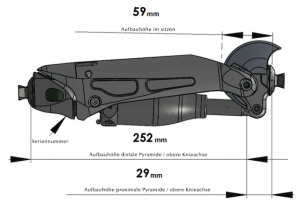

Technical data

The VGK-Go! is rated for up to 125KG, for K2, K3 and K4 users.

Choice of proximal interfaces:

The VGK-Go! comes with three interfaces:

- Proximal Pyramid: VGK125P

- Proximal M36 abutment: VGK125M

- Proximal Through Knee anchor: VGK125A

Class of Joint

The VGK is a fluidically controlled hydraulic knee joint as opposed to:

– electronically controlled hydraulics such as in C-leg-.

– using rheomagnetics such as in Rheo

– using hybrid pneumatics together with hydraulics such as in Hybrid/Synergy.

– plain mechanical designs such as 3R80

Stance Mode activation

The VGK-Go! is a default stance knee joint. (just like the C-leg, and Mauch SNS)

– as opposed to weight activation of stance mode as in 3R80.

– as opposed to geometric locking as in Total-Knee or as in other polycentric knees.

Stumble Recovery support

The VGK-Go! supports stumble recovery when the toe hits the ground prior to full extension.

-Stumble recovery support is not naturally present in knee joints .

-An example of a stumble recovery can be viewed.

Walking downstairs and downslope

The VGK-Go! supports leg-over-leg walking downstairs and down slope.

-The VGK-Go! has a remarkable steady action in the movement of the knee.

-The VGK-Go! is insensitive to any added weight being carried down stairs.

Thermal properties

The VGK-Go!, due to microkinetic control technology, provides significant compensation for the thinning out of the hydraulic fluids which can so easily cause loss of power in hydraulic knee joints.

-This thermal stability has been tested in the lab.

-This thermal stability has been tested in walking 600 steps downstairs.

-The frame of the VGK-Go! acts as a large cooling fin, literally drawing the heat out of the hydraulics.

Adaptive behaviour

The VGK-Go! is autoadaptive to user needs:

-The VGK-Go! speeds up when walking speed increases.

-The VGK-Go! stabilises movement walking downstairs and downslope.

-Terminal impact self regulates its strength.

Water resistance

The VGK is water resistant:

-For reasons of safety against the permissible depth of immersion under water , the maximum depth of use is waist-deep.

-See instructions for use.

Kneeling angle

The VGK-Go! has been constructed to allow maximum knee flexion in kneeling, socket permitting.

temperature stabilisation

Please see our “Fluidics in detail” page for further information on this.

WATERPROOF-NESS OF VGK

We are often asked about waterproofness of VGK.

Waterproof-ness in artificial limbs has meaning in a context of history. Where limb were made of wood, the wood would soften, swell and the prosthesis gets damaged within a day. Where the limb was made made of sheet metal, the rivets would corrode, and the steel would rust, making the prosthesis vulnerable to early failure, say within a year after regular exposure. When electronics are user, if not properly shielded, water may cause short circuiting, and the prosthesis will instantly malfunction.

The VGK knees are water proof to the following limited extent: the limb can be submersed but not used to a depth of 5 meters under water. ‘Not used’ to prevent risk of drowning due to negative buoyancy of the metals used in the joint. Premeditated use deeper than 1 m depth will invalidate warranty.

The VGK is satisfactory waterproof against salt and clorinated water if cleaned well with tap water afterwards. If not cleaned well, salt will dry up in high concentration and support corrosion, not unlike cars corroding with use near seasides. It is the nature of this chemistry, and this process is not under warranty but part of fair wear and tear.

There is no IP-rating for the VGK because the IP-rating relates to electrical goods, and the standard can therefore not be meaningfully applied to the VGK-Go! and VGK-S.

Since the VGK is known to you to use mineral oil for its hydraulic operation, Orthomobility cannot take responsibility for contamination of surface water when used in water. This is the responsibility of the user.

In practice the VGK can withstand use in water very well (no disruption to its function in the short term), over time, when not cleaned well white coloured powdery stains can be seen on the pyramids in some cases (due to metallic actions between titanium and adjacent metals), and when not cleaned well the bearings can show some brown coloured corrosion over time, which is all part of fair wear and tear.

IN SHORT: The VGK product range can be used in water, swimming, shower, rain, wading etc. without immediate dysfunction. Over longer term, depending on style of use and cleaning, minor surface corrosion damage may occur as part of fair wear and tear. The use in water is the users’ responsibility with regards to safety against drowning and surface water quality.

STORAGE

The VGK, when not used, must be stored in an EXTENDED position. This has got to do with the mechanisms that separate oil and air inside. An extended position is the position with the piston being pulled out as far as it goes!